Source of Crude Glycerine

Hydrogenation is a reaction of hydrogen addition at double bonds in the fatty acid chain. The degree of hydrogenation is directly related to the Iodine Value (IV) of fatty acid product.

There are 3 most common types of crude glycerine:

• Sweet water (From fat splitting process – Hydrolysis)

• Soap-Lye (From soap manufacturing process – Saponification)

• Biodiesel crude glycerine (From biodiesel production – Transesterification)

Impurities in Crude Glycerine

Typical crude glycerine contains the following:

• Glycerol

• Water

• Organic impurities (MONG)

• Salt (depending on the type of transesterification catalyst)

• Residual methanol (possible if produced from biodiesel process)

Glycerine Refining Process

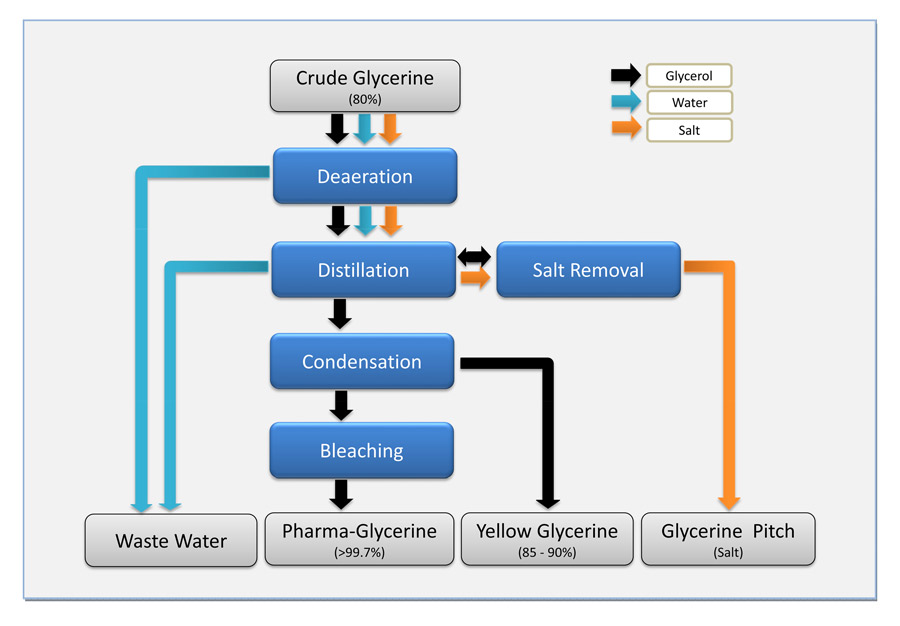

Glycerine refining process involves the following steps:

- Deaeration

- Distillation & Condensation

- Bleaching

- Continuous Salt Removal (optional)Process Description

a) Deaeration

Crude glycerine is first treated with sodium hydroxide. It is then heated and deaerated under

vacuum to remove residual moisture, methanol (if any) and un-dissolved gasses.

b) Distillation

Partially dried crude glycerine is fed to the distillation still for further heating under high

vacuum. Distillation is carried out by means of circulation within force-circulation heater

(using medium pressure steam) at temperatures of 160 °C. Top column pressure is maintained

at high vacuum to facilitate good separation efficiency

c) Condensation

Condensation of glycerine vapors is achieved in high efficiency structured packing and special distributors.

The high purity distillate 1 (>99.7%) is obtained from a hot condensation system

The glycerine from 2nd condensation system is recovered as technical grade glycerine (90%) (also known as yellow glycerine) or recycled back to glycerine pretreatment section.

d) Bleaching

Glycerine distillate 1 is filtered through activated carbon bed at 80 °C to remove color

e) Salt Removal

When glycerine is distilled, the non-boiling compounds (MONG, Salt, Soap, etc) are being concentrated.

Concentrated glycerine is periodically bled off to decanter system to remove salt as solid discharge.

Liquid residue from decanter will be sent to post distillation still where glycerine is distilled off further.

Process Features:

- Tailor-made design for crude glycerine feedstock with different quality and impurities

- High yield

- Refined glycerine product with low ester content and good color

- Continuous salt removing with decanter system particularly (*suitable for crude glycerine from biodiesel plant)